Housing/Mechanism manufacturing

We can handle all processes including housing design, pressing,

sheet metal processing, resin molding,

and cutting

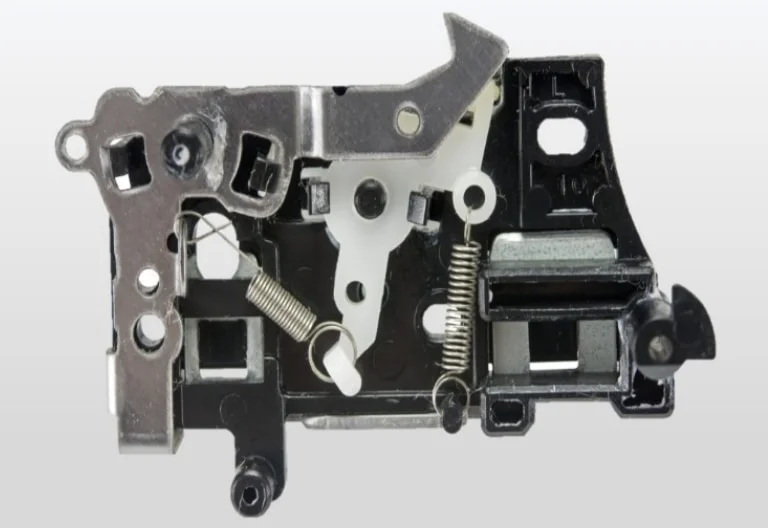

In addition to single components, we can make assemblies that combine molded parts with sheet metal parts, etc.

We resolve manufacturing challenges by leveraging diverse and abundant processing, assembly, and inspection

technologies and state-of-the-art equipment.

We respond to demands ranging from small lots to mass production items.

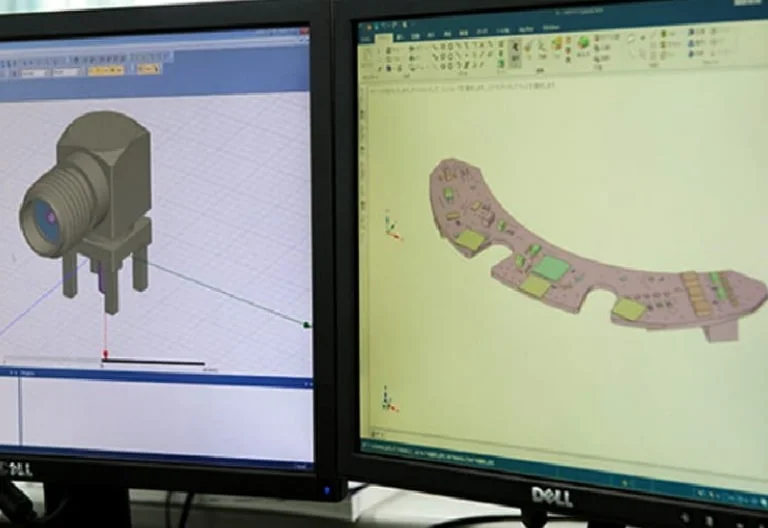

Housing design

We can implement 3D-CAD housing design and mechanism design.

Our experienced engineers will consult with you to transform your ideas into reality.

We can even accept requests based on rough sketches.

- Deliverable

- - 3D data / 3D-PDF / Dimensional drawings, etc.

Our CAD software

- Manufacturer

- Dassault Systemes

- Tool name

- SOLID WORKS

Housing design from a thorough understanding of “electronics”

We got our start in short lead type production of PCB prototypes.

Because we have a thorough understanding of electronics in general, we are able to propose housing designs that take circuit performance into account to the maximum extent possible.

Sheet metal processing

(compound fiber lasers, press brakes)

We conduct high-accuracy processing based on our extensive experience while taking into consideration the characteristics of each metal.

And we can work with precision sheet metal and thin sheet metal and implement housing processing, spot welding, thin sheet welding, and finishing from small to large lots with quick delivery.

- Minimum processing length of 3.2 mm with the

latest compound fiber lasers - Clean bending processing with the shortest fully

automatic step benders - Ability to handle aluminum, copper, SUS, and

other metals - Materials of sheet thickness 0.8 mm to 3. 2 mm

always in stock

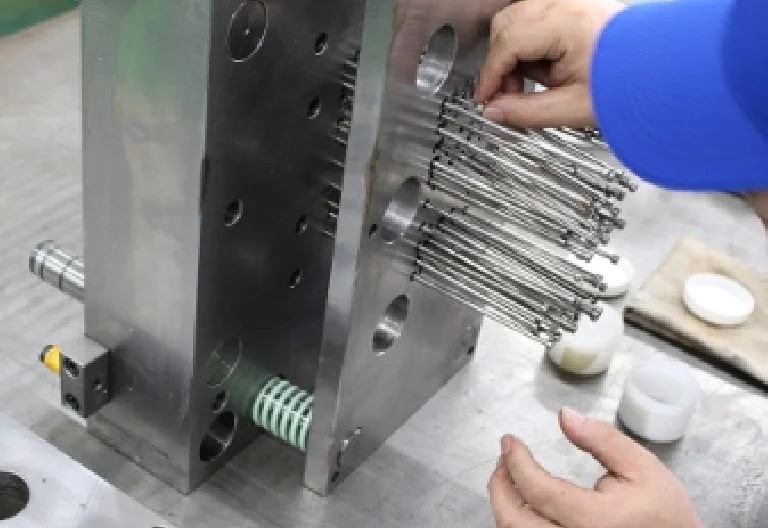

Pressing

The types of components installed vary depending on a product’s functions. And we can support a wide range of component types.

- We can handle a variety of processing, including progressive, single-stroke, and drawing.

- We use high-precision dies to provide high-quality, quick delivery, and low-cost press parts.

- Leave composite parts that combine press and resin molding to us.

Please consult with us about anything, including bus bars, resin composite products, and other special specifications!

Leave die production and maintenance to us too!

We support our customers’ manufacturing from the die design stage.

We also have in-house maintenance technology for die tools.

And we can handle die production both domestically and overseas.

Injection molding

From small to large lots,

we respond to needs for short lead times at low cost.

We also manufacture aspherical optical components and can also handle high-accuracy molding technologies and other optical systems.

- We have 20 general-purpose injection molding

machines ranging from 75t to 550t. - We can also handle ABS, PC, PP, BOM, PBT and

other materials. - We have a clean room (class 10000) and various

press-fitting devices.

Cutting

We produce metal processed components, which need to have high reliability, with emphasis on precision, materials, cost and lead time.

We can work with a wide range of materials including iron, aluminum, stainless steel, and copper.

Mechanical units

We handle everything from parts manufacturing to product assembly, combining parts that have been processed in housing design and sheet metal processing (press, laser, press brake), resin molding, and cutting stages for the finished (or semi-finished) product.