PCB manufacturing

- General PTH PCBs

- High density

- High heat-dissipating and thick copper

- High-speed communication and high-frequency

- Multilayer and high aspect ratio

- Flexible

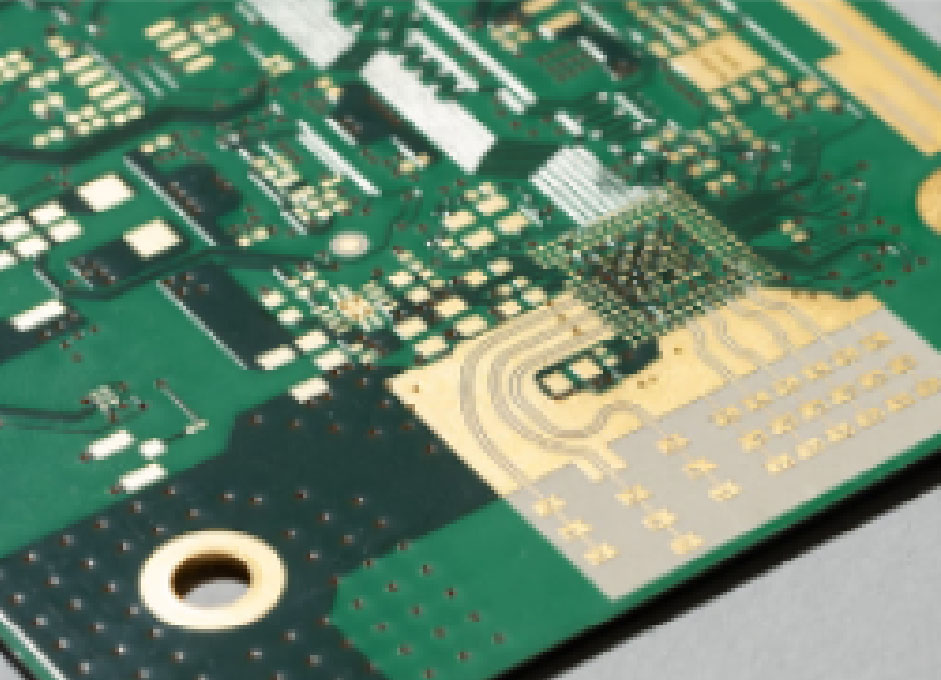

General PTH PCBs

Consisting of circuit wiring and insulating base material to move electronic components as per the required function, common double-sided PCBs and multilayer PTH PCBs are used in a wide variety of products.

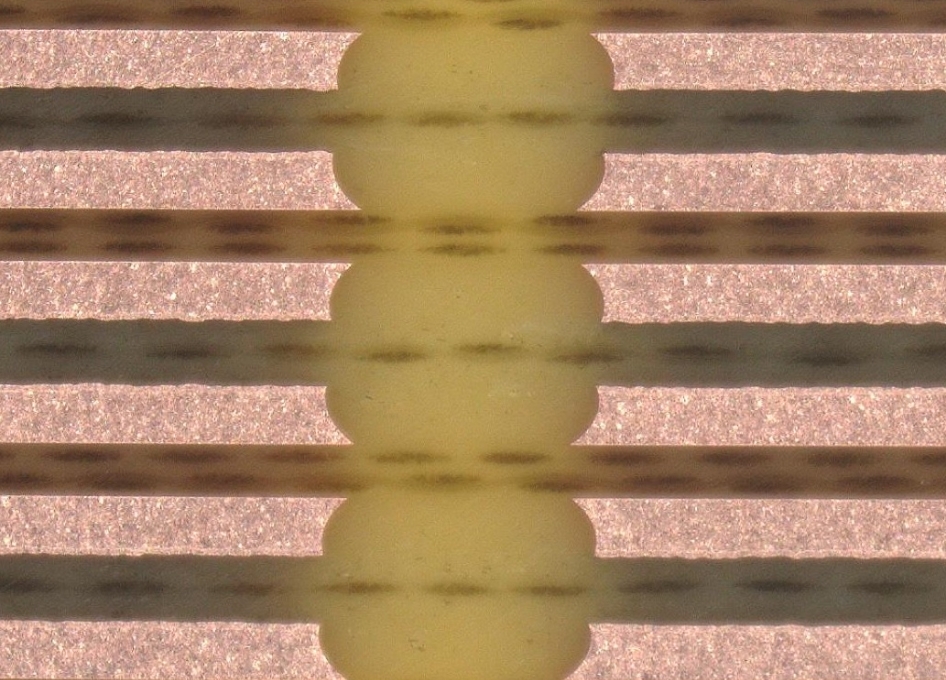

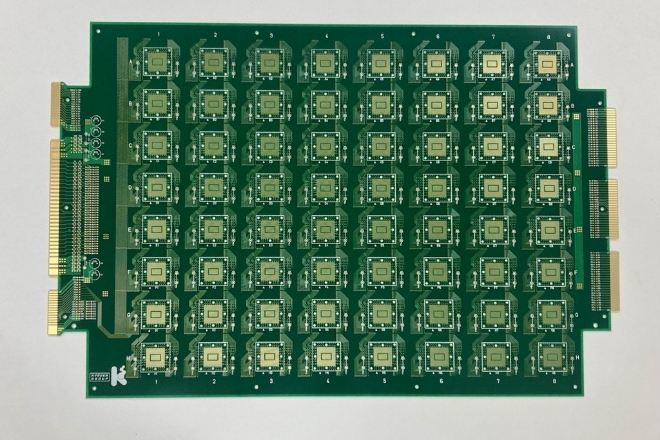

High-density circuit boards

We provide High-density interconnect (“HDI”) with pad-on-via and high-density wiring using laser via technology and filled plating technology.

High heat-dissipating and thick copper circuit boards

These address the heat issues associated with high-current handling in large-capacity data communication and high-speed processing EVs, etc.

High-speed communication and high-frequency circuit boards

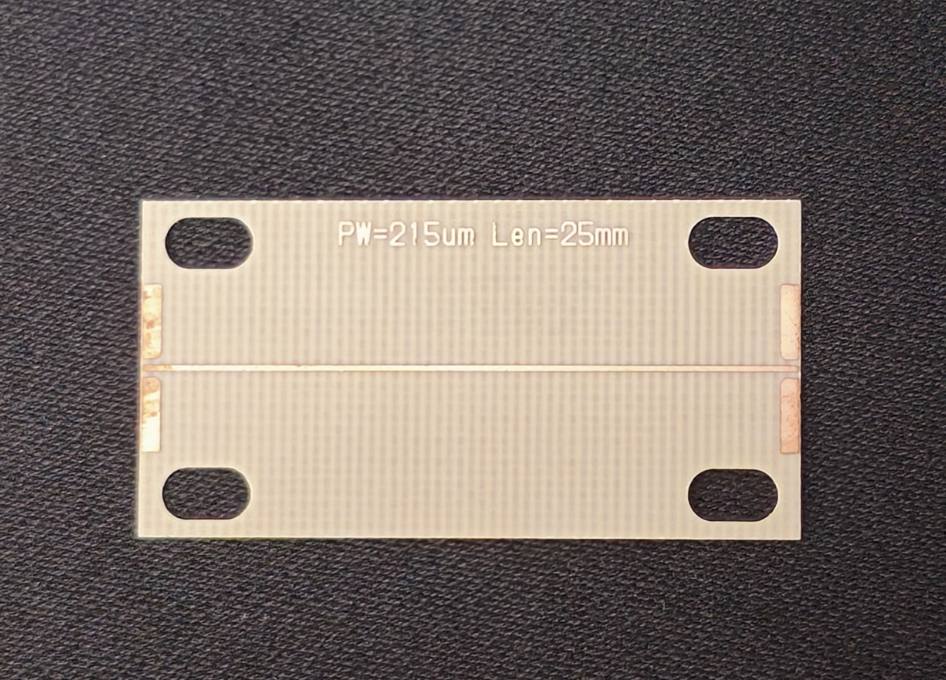

We propose substrates to reduce the “transmission loss” of high-frequency signals used in high-frequency equipment, and provide products with controlled impedance.

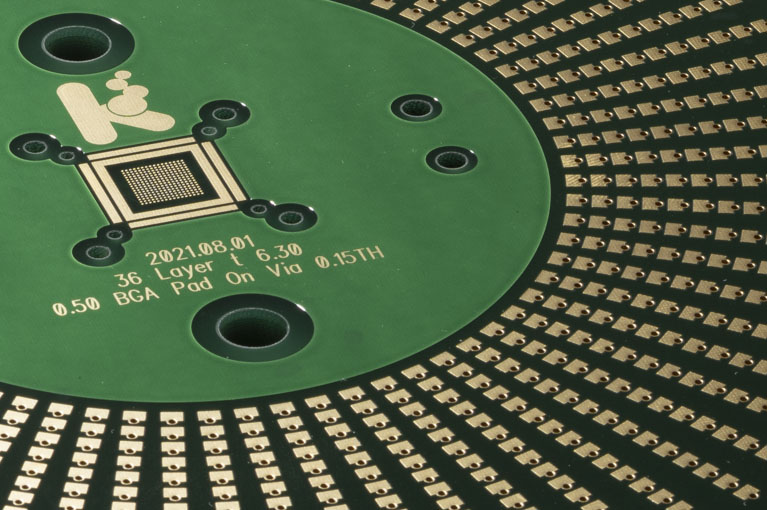

Multilayer and high aspect ratio circuit boards

We provide multilayer, high aspect ratio circuit boards because the total board thickness of PCBs also needs to be thicker in proportion to the increase in the number of wiring layers (increase in the number of layers) and the multilayer structure associated with the high integration and high density of electronic devices.

* Aspect ratio = board thickness ÷ hole diameter

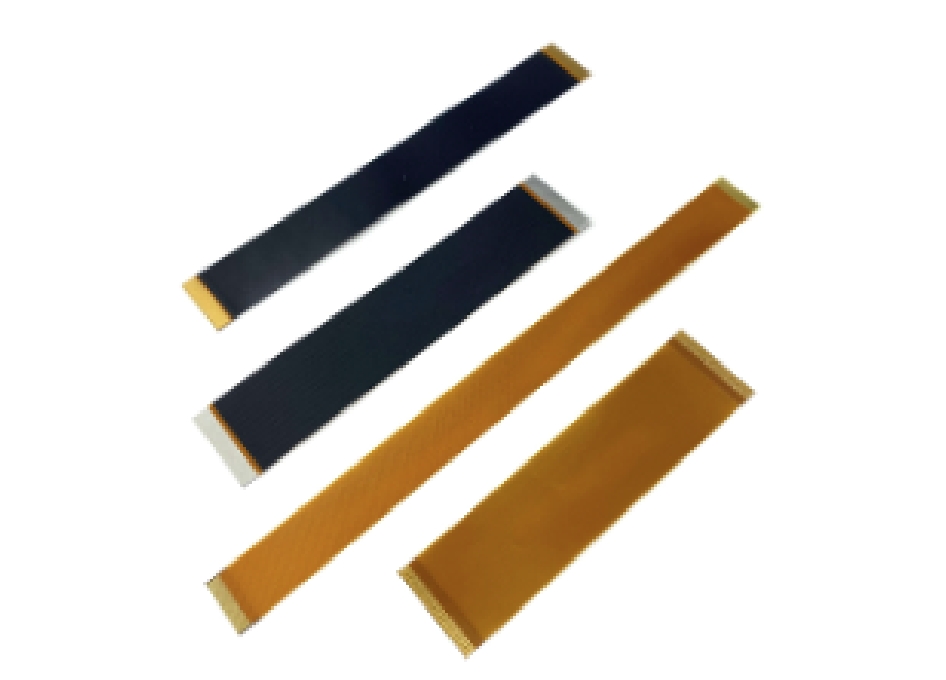

Flexible circuit boards

Unlike rigid printed circuit boards, these are thin and bendable printed circuit boards.

-

Single-sided/Double sided/multilayer PTH PCBs

-

High-density interconnect (“HDI”)

-

HDI Any Layer PCBs

-

Heavy Copper PCB

-

Metal base heat-dissipating PCBs

-

High heat-dissipating PCBs(high-speed heavy copper plating)

-

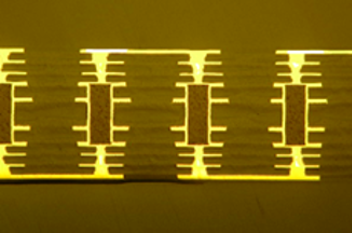

High Frequency Millimeter-wave PCB

-

High-speed transmission PCBs

-

RF module PCBs

-

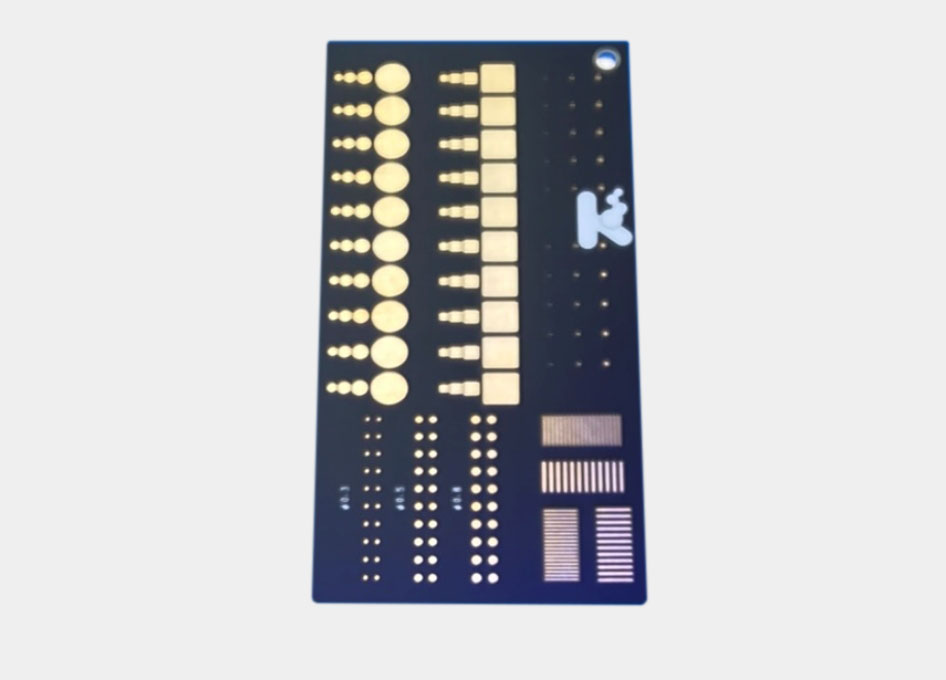

Semiconductor Testing PCB

-

High-multilayer PCBs

-

Flexible PCBs