Component Mounting

From small lot prototyping to mass production, from large

boards to high-density mounting

We can respond to your needs with the latest equipment and

state-of-the-art technology.

Having experience of mounting all kinds of products ranging from large boards to high-density mounting,

we can also handle high-difficulty mounting with the latest equipment and cutting-edge technologies.

Moreover, we respond to the needs of customers with integrated services ranging from remodeling, reboring,

reworking and electrical inspection to assembly.

KYODEN Group internally conducts metal mask manufacturing and can also respond to orders for mounting

and assembly in quick delivery.

High-density Mounting

As electronic products become thinner and more compact, high-density mounting technology and equipment capacity are important elements.

Having installed the latest equipment and inline print inspection machines capable of producing multi-pin BGAs (FPGA, etc.), 0201 capacitors and other high-density mounted products, KYODEN Group supplies high quality products in quick delivery.

Reflow Mounting

Many products in recent years feature the mixed mounting of FPGA components, small CR,connector components and so on.

When simultaneously mounting large and small components, because the amount of solder varies according to the pad size, the method of conveying the temperature is very important.

Thanks to our extensive record of prototype mounting, KYODEN has numerous reflow mounting profile conditions.

We achieve high-quality mounting by preventing the occurrence of failed connections, etc. caused by non-melting of solder.

Diverse Component Mounting

We mount various components according to the features of products.

KYODEN can work with a diverse range of components.

| BGA/CSP | Large capacitor | QFP |

|---|---|---|

| LGA | Axial/Radial components | Press fit |

| QFN | Ultra-small components (0603/0402/0201) |

Special connectors |

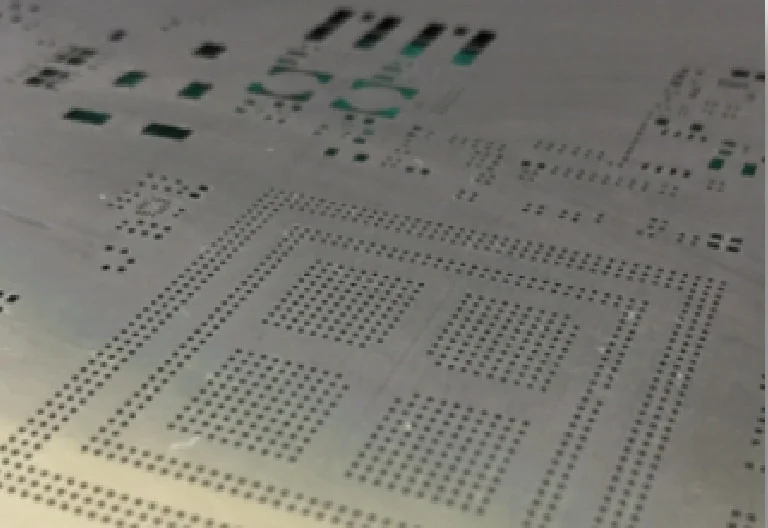

In-house Metal Mask Manufacture

Responding to needs for mounting in fast delivery time, we introduced metal mask processing machines 10 years ago. Utilizing our accumulated store of data, we realize the ideal solder quantity from the prototype stage.

Since there are also cases where quality does not stabilize even when products are manufactured according to the data sheet, depending on the component, it is important to correct openings.

Automatic Coating

In recent years, due to the increase in IoT devices and so on, we are increasingly receiving orders for post-mounting coating.

We conventionally implemented brushing or spray coating upon masking the areas where the coating with moisture-proofing material was prohibited,

however, we have now introduced moisture-proof coating machines.

This has removed the need for excessive masking and allows us to supply PCBs with stable finish.

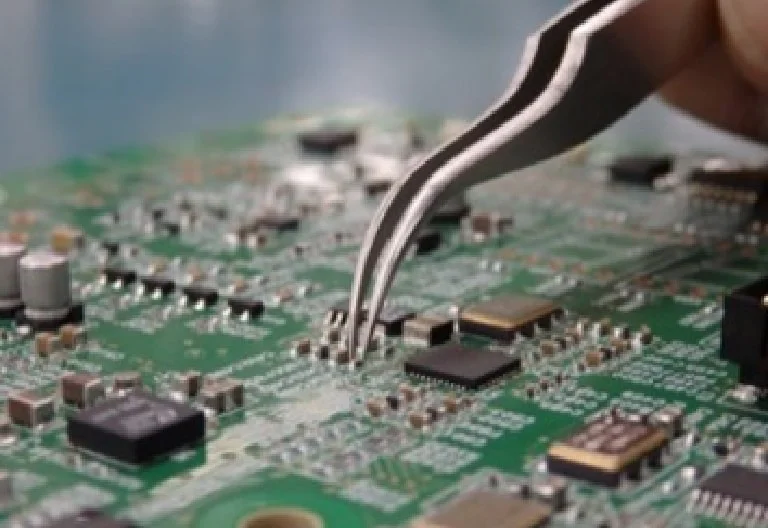

Rework and Remodeling

With recent small components, BGA components and the like, it is very difficult for customers to independently conduct reworking and remodeling.

KYODEN offers remodeling services by national qualification holders and can conduct removal and remounting using rework devices.

In addition to the products we make, we can also remodel products that have been manufactured by other companies.

With procurement of components becoming increasingly difficult, be sure to utilize KYODEN’s solutions.

Hand Soldering and Hand Mounting

KYODEN can also respond to orders for hand soldering and hand mounting.

Please contact us for cases of small-volume products and cases in which it is difficult to use automatic machines.

Our craftsmen can respond to needs for hand soldering down to a minimum size of 0402.

Quality Control

We have introduced inspection machines to ensure the quality of mounting.

- Print inspection machine: This conducts three-dimensional measurement

of the quantity of cream solder printing and numerically controls area,

volume, bleeding, blurring, etc. - Image inspection machine: This conducts 2D and 3D inspection of the

solder condition, mounting direction, and whether or not mounting has

been performed. - X-ray inspection machine: This covers BGA, LGA and other elements that

cannot be confirmed from the outside.

100% LOT Control

KYODEN Group has secured a system for ensuring traceability of all mounted products. To minimize ripple effects arising from nonconformities,

we maintain a database of mounting information that lets us know on which lines mounting is implemented.

QR code printing is also possible. In this way, we have established a reputation for stable production and stable quality.

Production equipment

SMT Line Composition

| Printers | Print Inspection Machines |

Coating Machines |

Mounting Machines (Chip) |

Mounting Machines (Irregular) |

Mounting Machines (Irregular) |

Mounting Machines (Irregular) |

Mounting Machines (Irregular) |

Reflow Furnaces |

|

|---|---|---|---|---|---|---|---|---|---|

| SMT | NPM-GP/L PFSC |

KY8030-3 KOH YOUNG |

CPD-1000VL SUZUKI |

NPM-W2 PFSC |

NPM-W2 PFSC |

NPM-W2 PFSC |

ー | ー | NJ611L-102 EIGHTECH |

| SPG PFSC |

KY8030-3 KOH YOUNG |

ー | CM602-L PFSC |

CM401-L PFSC |

DT401-F PFSC |

ー | ー | NJ611L-102 EIGHTECH |

|

| SPG PFSC |

NVI-S300 TECHNO HORIZON |

ー | NPM-W2 PFSC |

AM100 PFSC |

ー | ー | ー | SNR-850 EIGHTECH |

|

| SP-60PL PFSC |

NVI-S300 TECHNO HORIZON |

ー | CM602-L PFSC |

DT401-F PFSC |

ー | ー | ー | NJ611L-102 EIGHTECH |

|

| SPG2 PFSC |

NVI-S300 TECHNO HORIZON |

ー | NPM-W2 PFSC |

NPM-W2 PFSC |

NPM-W2 PFSC |

ー | ー | NN152M-102 EIGHTECH |

|

| YVP-Xg YAMAHA |

ー | HSD-Xg YAMAHA |

YG200L YAMAHA |

YV100XTg YAMAHA |

YV100XTg YAMAHA |

YV88Xg YAMAHA |

YG88 YAMAHA |

NIS-20-82-C EIGHTECH |

|

| SP60PM PFSC |

NVI-S300 TECHNO HORIZON |

ー | CM402-M PFSC |

DT401-M PFSC |

ー | ー | ー | NJ611L-102 EIGHTECH |

Automatic Insertion Machines, Soldering Machines, AOI, etc.

| Assembly & Inspection |

Metal Mask Makers |

SMD Towers |

X-ray Reel Countters |

AOI | ICT | X-ray Inspection Machines |

Automatic Soldering Machines |

Local Soldering Machines |

BGA Rewoking Machines |

Automatic Coating Machines |

Laser Marker |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 4 | 1 | 8 | 5 | 4 | 3 | 5 | 3 | 1 | 1 |