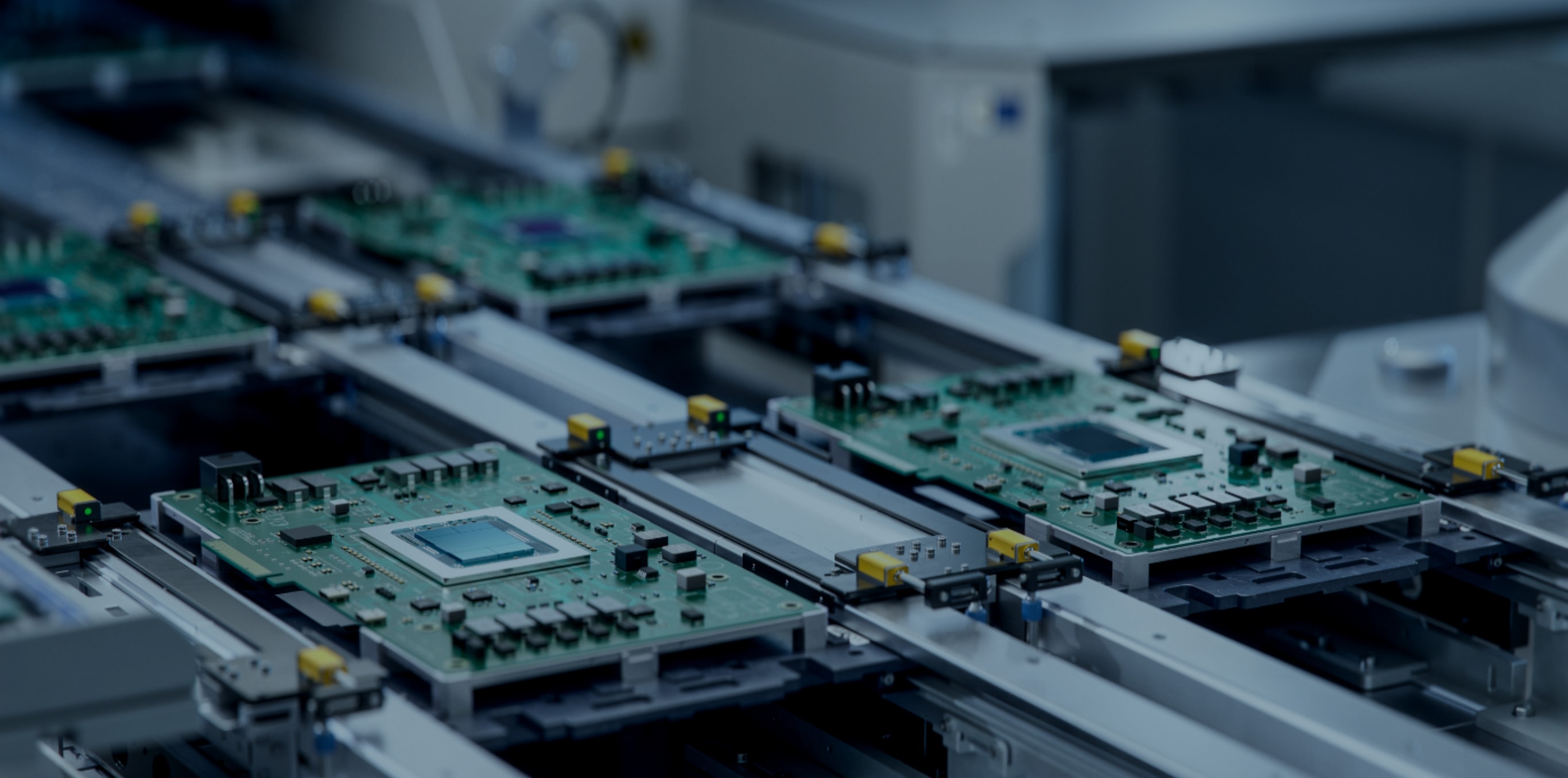

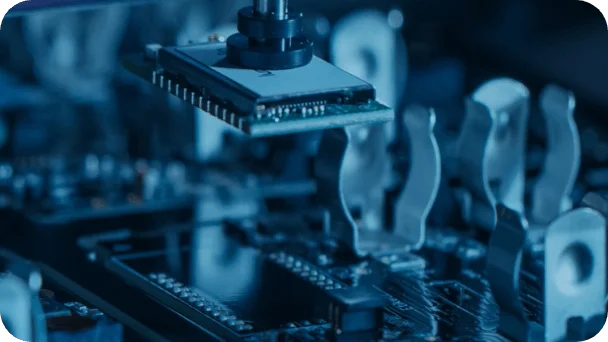

We respond to our customers’ product development

issues by providing total in-house integrated production

From planning and development to completion of electronic devices, we solve various issues that our customers face through our fully integrated in-house production system.

Of course, from prototyping to mass production.

We have many advantages in cost reduction, quality control, and delivery time.

Please experience the overwhelming convenience of KYODEN’s one-stop service for complete in-house production.

Development to FinishingTotal In-house Integrated Processesfrom

Merits of One-Stop Solutions

Unified Communication

There is no need to spend a lot of time having meetings and coordinating between multiple operators as would be the case if, for example, Company A was responsible for PCBs, Company B was responsible for mounting, and Company C was in charge of final assembly.

You can trust KYODEN to control all process centrally.

All you need to do is communicate your needs to our sales representative. If you wish, we can also arrange for specialists in the fields of circuit design, housing design and PCB to attend meetings.

Clarification of Quality Assurance

f there are multiple contractors, the whereabouts of manufacturing responsibility tends to become blurred.

If you make a package consignment to KYODEN, you can be confident we will deliver finished products.

Thanks to our extensive track record in manufacturing, we can make and deliver products with confidence.

You can be confident regarding quality assurance too.

Total Cost Reduction

We support customers with a broad product lineup and urement capability based on central buying.

The same production line and plant from prototype to mass production minimizes initial costs.

Because we provide one-stop solutions, costs can be cut from the development stage.