Total In-House Production

STEPContact

Feel free to consult with us at any time.

KYODEN has 15 sales offices in Japan and 4 overseas. Please feel free to first contact us at your nearest sales office or through our website. A dedicated sales representative will assist you.

STEPProduct planning

We hold hearings on the image held

by the customer and work to make

that a reality.

We make a reality out of customers’ ideas of “we want to make this and have these functions.” Proposals are offered in areas from planning to optimal technology and manufacturing methods, based on the reliable technologies and know-how we have cultivated over many years.

- Requirements definitionSpecifications and design study

- Design registration proxy

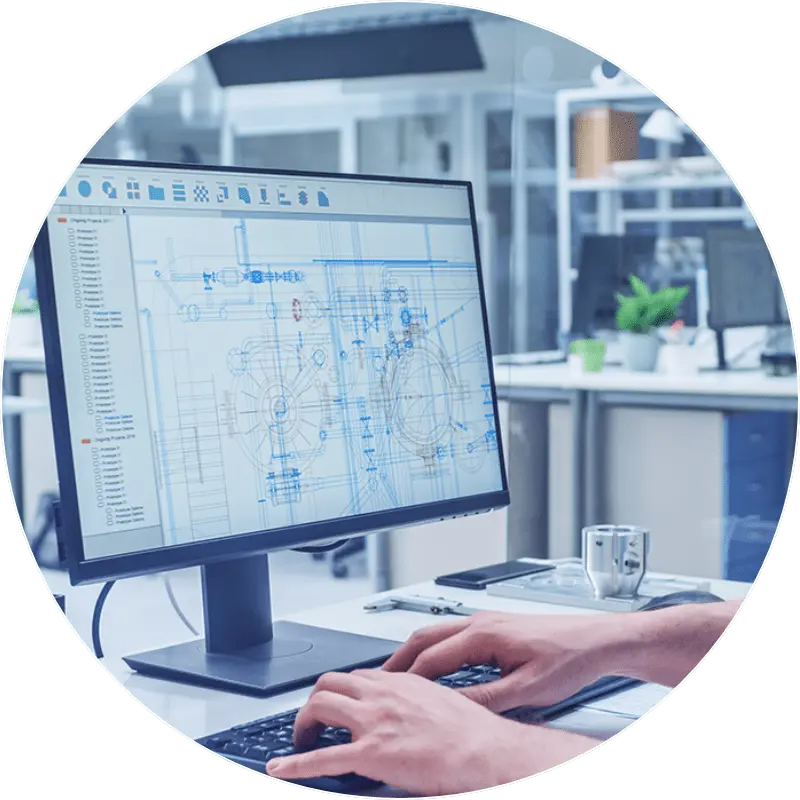

STEPDevelopment and design

A wide range of design solutions are

provided from electric to mechanical.

We can provide all the solutions required in the development process in-house, from circuit and software design to PCB design, housing design, and various types of analysis. Rework is minimized and yields improved through optimal proposals by engineers who know manufacturing inside out. We can shorten development time, improve quality, and reduce costs from the upstream stage of manufacturing.

- Circuit design

- FPGA design

- Software design

- Housing/machinery design

- PCB pattern design

- Analysis simulationSI, PI, EMI, electromagnetic field, thermal fluid

STEPProcurement

We can procure all the necessary

materials for your products.

We handle not only electronic components, but also a wide range of mechanical parts such as housings, as well as harnesses and assembly screws. You can also leave the troublesome task of parts inventory management to us.

- Electronic components

- Mechanical parts

- Raw materials

- Packing materials

- Inventory management

- EOLInvestigation and procurement of discontinued products

- Proposal of alternative parts

STEPPCB manufacturing

A broad-ranging manufacturing lineup

according to the usage covers products

from single-sided to multilayer PCBs

and High-density interconnect (“HDI”).

From the short lead-time manufacture of a single board to the manufacture of PCB products in small and medium-sized lots, we respond to the demands of customers with a diverse lineup of products centered around High-density interconnect (“HDI”) and multilayer PCBs.

- Single-sided to multilayer through-hole PCBs

- High-density interconnect (“HDI”)

- High-speed communication and high-frequency circuit boards

- High heat-dissipating and thick copper circuit boards

- Multilayer and high aspect ratio circuit boards

- Flexible PCBs

STEPComponent mounting

We can handle a wide range of

mounting techniques, from the use of

cutting-edge equipment to manual

mounting by skilled workers.

We are fully equipped with SMT lines capable of mounting 0201 size. We also handle in-house production of metal masks.

Stable production and quality are achieved through 100% inspection.

- Mounting by mountersHigh-density mounting, 3D mounting, BGA mounting

- Spot reflow

- Press-fit mounting

- Bare chip mounting

- Hand soldering and hand mounting

- Metal mask manufacture

- BGA reballing, reworking

- Coating

STEPHousing/machinery production

We offer means of manufacturing that

fit your needs from small to large lots.

With the technologies we have accumulated and state-of-the-art equipment, we offer the optimal means of manufacturing, including pressing, sheet metal processing, injection molding, die manufacturing, painting, cutting, and welding. We can also provide assemblies combining molded and sheet metal parts, etc.

- Sheet metal processing

- Pressing

- Injection molding

- Die manufacturing

- Painting

- Cutting

- Welding

STEPAssembly

We are fully equipped with flexible

lines according to products.

Assembly is done there to achieve finished products.We assemble products in-house into finished products. We also prepare cables and connectors to be connected to the products, process harnesses, and manufacture specialized jigs and tools.

- Product assembly

- Unit assembly

- Jig and harness manufacturing

STEPOperation check, quality assurance,

and after-sales maintenance

We provide a wide range of inspections

according to customer requirements.

We perform operation tests to ensure that finished products operate properly. We provide a wide range of inspections, including total inspection and sampling inspection.

- Function & measurement

- Environmental testing

- Legal acquisition application

- Maintenance

STEPDelivery

Everything from planning

to finished product is

available from

a single point of contact.

Leave it to KYODEN to shorten

product development time,

reduce costs, and improve quality.

NEXT CONTENT