Delivering finished products by product planning and development to design, procurement, manufacturing, mounting, and assembly

Total In-House Production

From product planning to completion, we handle everything in an integrated manner in our own plants.

As a “total in-house production EMS manufacturer,” we provide a full range of support, and we can also handle domestic and overseas mass production from any process, even just a single prototype board. Please make use of KYODEN as a convenient plant!

PLANNING

PLANNING

DESIGN

DESIGN

MANUFACTURE

MANUFACTURE

HOUSING

HOUSING

MOUNTING

MOUNTING

ASSEMBLY

ASSEMBLY

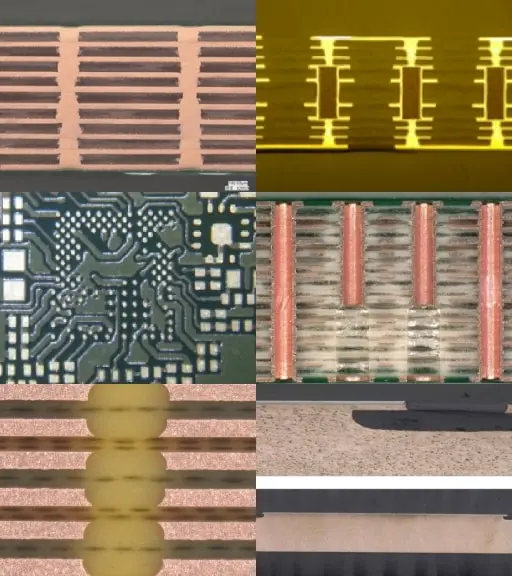

Technical development meeting new market needs

KYODEN’s cutting-edge technologies

Our business spans work from familiar areas of daily life to areas that support industry and various operations and areas where cutting-edge technology is required.

We are developing cutting-edge technologies such as 5G communication-compatible/multilayer/High-density interconnect (“HDI”) and high-frequency/high-density/high heat-dissipation/high-current PCBs.

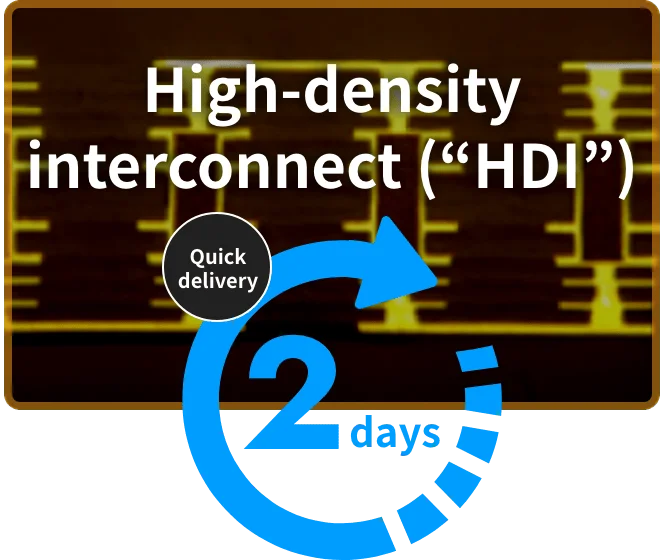

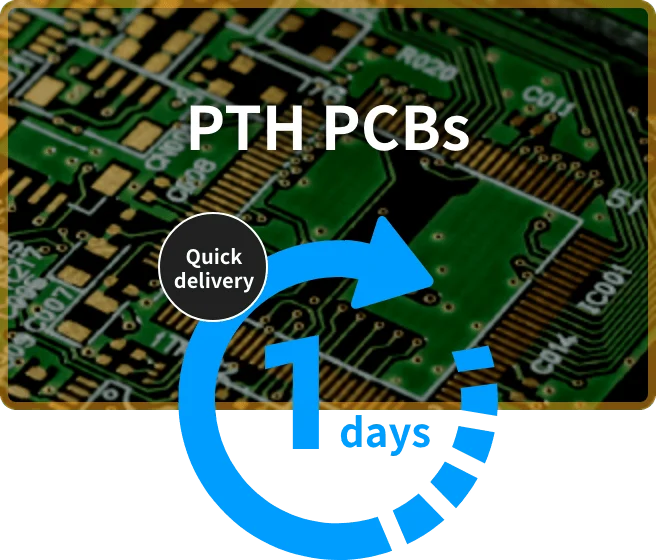

PTH PCBs, High-density interconnect

(“HDI”), and EMS

Provided with industry-

leading quick delivery

Overwhelmingly quick delivery of one day for through-hole PCBs

and two days for High-density interconnect (“HDI”) are achieved.

“Miracle α” service, the fastest in KYODEN’s history, was also launched.

We contribute to our customers’ product development with

KYODEN’s prototype rapid manufacturing service that bring

products to market quickly.

Quick delivery x Low cost x High quality full range of support

Trustworthy mass production structures in Japan and overseas

With five plants in Japan as the core, we also have KYODEN (Thailand), the main plant in the global supply chain, as well as a partner plant in China. A full range of support is provided from prototyping to mass production.