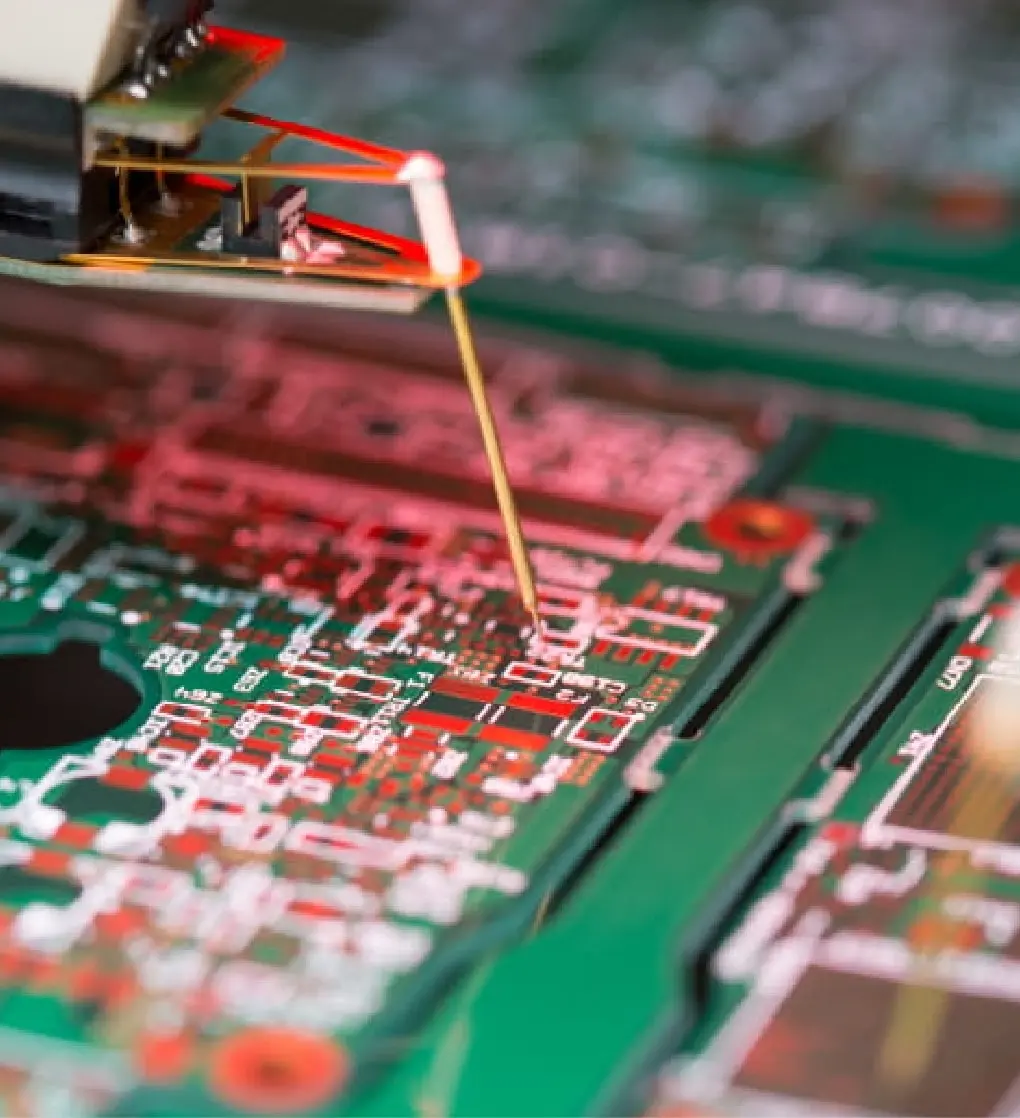

Mass production system in Japan and overseas

Trustworthy mass production

system in Japan and overseas

With five plants in Japan as the core, we also have KYODEN (Thailand), the main

plant in the global supply chain, as well as a partner plant in China. A full range

of support is provided from prototyping to mass production.

-

Overwhelming

cost proposal

capabilitiesWe have a diverse range of work sizes and a wide lineup of substrates, and we can respond to customer needs with our overwhelming proposal capabilities.

-

Same line,

stable qualityAll of our plants have obtained ISO certification, and we have established a consistent quality assurance system. We guarantee stable quality by conducting all work from prototype manufacture to mass production in the same plant and on the same line.

-

Reassurance

from a BCP

perspective as

wellA sense of security arises from having alternate locations. Recovery is possible even in the event of an emergency.

Why not review the cost of mass-

produced PCBs?

Improve costs with overseas manufacture.

Overseas mass production reference prices

| Double- sided |

@$55~ | Lead time starting at 20 days for 20 m2 |

|---|---|---|

| 4 layers | @$80~ | Lead time starting at 30 days for 10 m2 |

| 6 layers | @$105~ | Lead time starting at 40 days for 10 m2 |

We also handle quick delivery of mass-produced PCBs in Japan, and as a pioneer in quick delivery, we are accelerating the reduction of lead times for mass-produced PCBs as well

Domestic mass production working days

| Up to 10㎡ |

Up to 20㎡ |

Up to 50㎡ |

Up to 100㎡ |

|

|---|---|---|---|---|

| Double- sided |

From 10 days |

From 13 days |

From 15 days |

From 18 days |

| 4 layers | From 13 days |

From 15 days |

From 18 days |

From 20 days |

| 6 layers | From 15 days |

From 18 days |

From 20 days |

From 23 days |

* Prices and lead times may differ according to specifications and conditions. Please inquire for details.

Extensive lineup of materials

Please feel free to consult with us regarding special substrates.

| Panasonic | R-1566 |

|---|---|

| R-1705 | |

| R-1755 | |

| R-1766 | |

| R-1786 | |

| R-1787 | |

| HIPER Series(C,D,E,S) | |

| MEGTRON Series(4,6,7) | |

| Nan Ya Plastics | CEM-3-10 |

| FR-4-86UVBlock | |

| NP-140TL | |

| NP-155 | |

| NP-155FTL | |

| NP-175FBH | |

| NPG-151 | |

| Resonac | MCL-E-679FG(S) |

| MCL-E-679FG(R) | |

| MCL-E-700G | |

| MCL-LW-910G | |

| Shengyi Technology | S2600F |

| S1000H | |

| S1141 | |

| ROGERS | DiClad527 |

| RO4350B | |

| RO3003 |

| Sumitomo Bakelite | ELC-4756 |

|---|---|

| ELC-4762 | |

| ELC-4765 | |

| ELC-4970 UV(CEM-3) | |

| EMC | EM-528K |

| EM-370Z | |

| EM-526 | |

| EM-890K | |

| Nikkan Industries | L-6504C2UV |

| L-6524C2UV | |

| L-6554C2UV | |

| L-6705C2UV | |

| Risho Kogyo | CS-3556S |

| CS-3465V | |

| CS-3355W | |

| CS-3376CN | |

| CS-3945 | |

| CS-3376CX | |

| Mitsubishi Gas Chemical BT resin |

CCL-HL820 |

| CCL-HL832NSF | |

| CCL-HL972LFtypeLD | |

| Chukoh Chemical Industries | CGP-500A |

| Nippon Rika Industries | NRA-8 |

| Nippon Pillar Packing | NPC-F260A |

| Wazam | HA150LF |

We provide a stable supply chain by our

manufacturing centers forming a structure where

they complement each other

KYODEN’s strengths can also be found in the large number of fields we handle and our numerous manufacturing centers. All the centers have earned the praise of customers thanks to our cutting-edge equipment and maintenance of strict management. Based on cooperation between these centers, we realize mutually complementary functions capable of responding to any abnormal situation.

Tohoku Plant

Production capacity/34,000㎡

- Through-hole PCBs(up to 12 layers)

Main products manufactured

- Amusement machines

- Automotive devices

- AV-related devices

- Battery devices

Nagano Plant

Production capacity/21,000㎡

- Through-hole PCBs(up to 74 layers)

- Buildup PCBs (up to two stages)

Main products manufactured

- Measurement devices

- AV-related devices

- Telecommunications devices

- Electronic devices

Osaka Plant

Production capacity/13,500㎡

- Through-hole PCBs(up to16 layers)

- Buildup PCBs (up to four stages)

Main products manufactured

- Optical devices

- High-frequency devices

- Sensors

Thai Plant

Production capacity/130,000㎡

- Through-hole PCBs(up to 14 layers)

Main products manufactured

- Automotive devices

- OA-related and office equipment

- Home electronics and AV-related devices

Shizuoka Plant

EMS

- Component mounting, assembly, mechanical manufacture

Main products manufactured

- Parts procurement

- Component mounting

- General parts processing (resin molding, sheet metal processing, pressing)

- General unit assembly

- ODM business

Support from prototype to mass production

Because we are a manufacturer that handles everything from prototype

to mass production,

the quality, reliability, production

efficiency, price, etc., required for

mass production

is taken into account from the prototype stage,

to manufacture products with mass production in mind.

Prototype

- Selection of materials and methods

with mass production in mind - Consideration of the requirements

for mass-produced products - Application of information

on the manufacturing processes

for prototypes

Mass production

- Feedback of information to prototypes

- Speedy transition to mass production